1.Prefabricated Tops 2.Veined Collection

3.Mono Collection 4.Sparkle Collection

5.Metal Collection 6.Multiple Collection

Silica Free Stone Benchtops - More Health & More Care

Following the Australian Federal Government’s decision to ban engineered stone containing crystalline silica from 1 July 2024, we want to reassure you of our commitment to safety, quality, and our ongoing innovation of cutting-edge, thin, light-weight surfaces with our Silica Free Benchtops.

Bestone Silica Free Benchtop is made from Amorphous Silica instead of Crystaline Silica. Amorphous Silica has a stable molecular structure which is much less hazardous to human lungs than Crystalline Silica. The material is commonly found is glass, which helps erase any concerns or confusion arising from these recent decisions.

Ordinary users can rest assured that Bestone Silica Free Benchtops are entirely safe used in home and what's more do no harm to people who cut, polish, fabricate or install them.

Crystal Grey Quartz, Light Grey Silica Free Stone

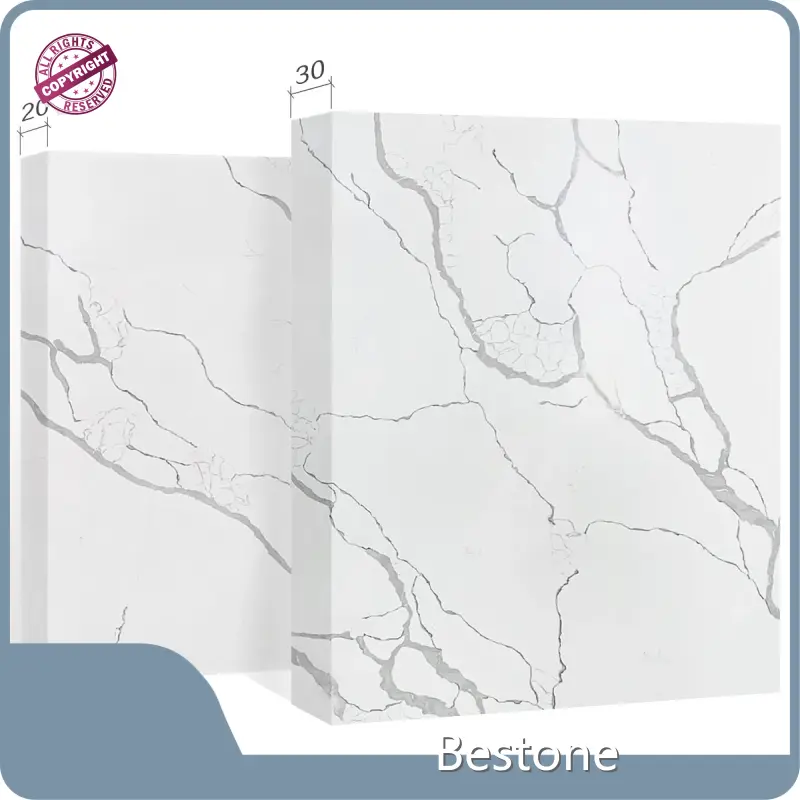

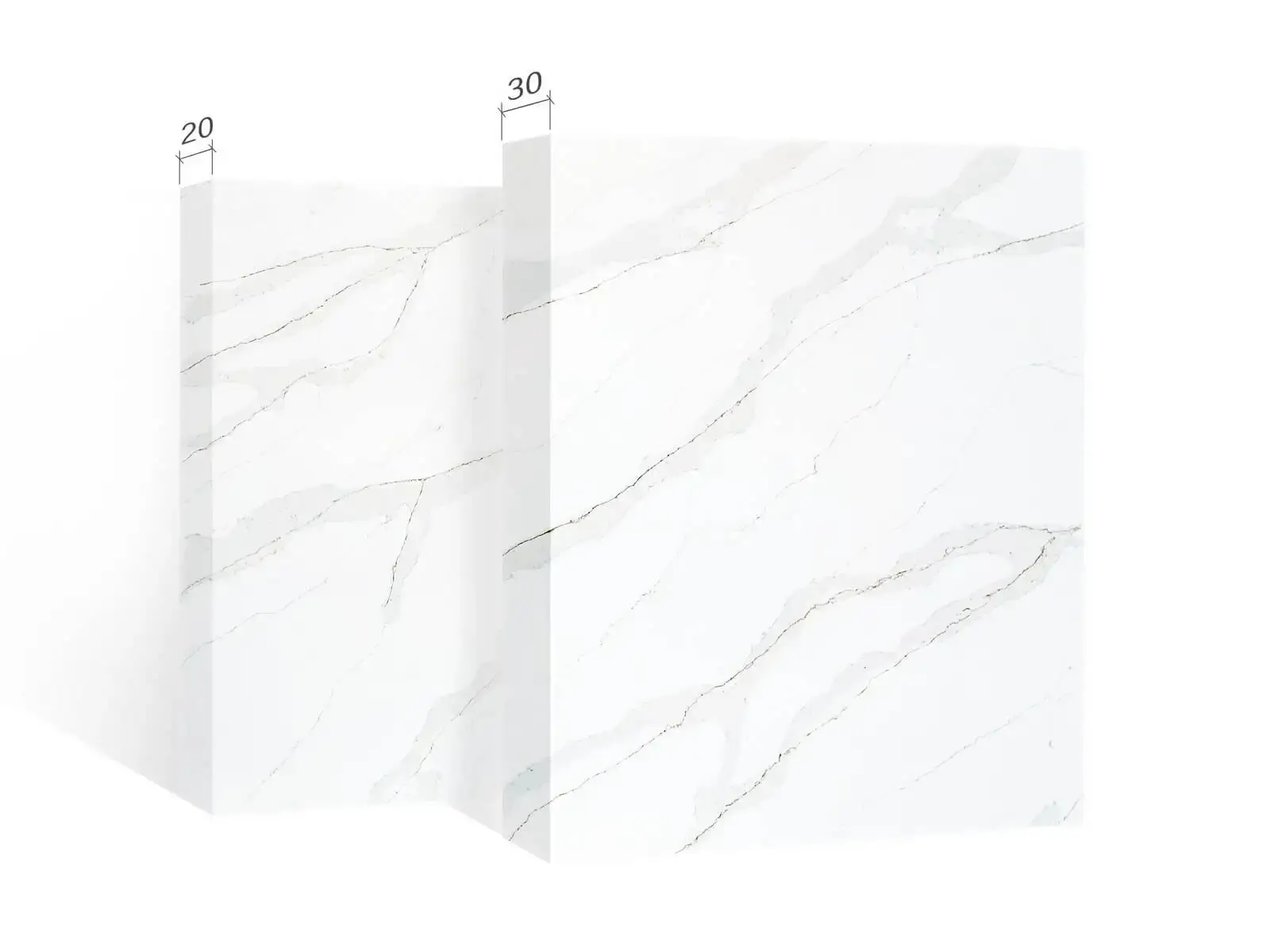

BESTONE has over 150 silica free stone colors with standard slab sizes like 3200 x 1600mm (126” x 63”) and 3000 x 1400mm (118” x 55”), as well as available customized sizes 2500~3200mm x1200

~1600mm, in thickness of 12/15/18/20/25/30mm. A wide range of colors and patterns such as Marble Imitation, Calacatta, Black Veined and other colors give us a very competitive and leading position in the global market.

Reference

| Slab size Available | 3500*2000mm, 3200*1600mm, 3000*1400mm |

| Cut tile sizes | 400*400, 600*600, 800*800 mm |

| Sand hole | None |

| Tone & Figure | Consistent |

| Flatness | <0.1mm |

| Angle | <0.2mm |

| Density | 2.3~2.5g/cm3 |

| Water absorption | <0.05% |

| Flexural Strength | 25~35Mpa |

| Compressive Strength |

>200Mpa |

| Moh’s hardness |

6~7 Degree |

| Glossiness |

>55 Degree |

| Thickness |

12, 15, 18, 20, 25, 30mm |

All Bestone quartz surfaces are easy to clean and maintain. Our non-porous quartz surfaces require minimal maintenance - there’s no need to seal or wax the surface.

Quartz Stone is very widely used for countertop, kitchen top, vanity top, table top, kitchen island top, shower stall, tub surround, bench top, bar top, wall, floor in Airports, Metro Station, Shopping Center, Hotel, Restaurant, Bar, Cafe, Apartment, Office and so on.

BESTONE is well equipped with automatic fabrication facilities.Automatic Infra-cutting machine, Automatic Sink-Cutting Machine and Automatic Polishing Machine are set for fabricating to highest standard of Kitchen Countertops, Vanity Tops, Bar Tops, Shelf Tops, Table Tops, Window Sills, Thresholds, Bath Room Tubs, and Bath Room Walls and so on.Different edge profiles, like Eased Edge, Pencil Edge, Laminated Edge, Mitered Edge, Bull-Nose and etc, are provided directly to Contractors, Dealers, Hotel Owners, and Fabricators all over the world. A professional project team responsible for color matching, shop drawings, book-matched tops, quality inspection and control, is an absolute guarantee for all our customers.

Boasting a dedicated team of over 200 members devoting to R & D, production, marketing and after-sales service for the quartz stone products and covering an area of 30,000 Sqm, at present BESTONE has Four sets of fully automatic production lines for quartz stone slabs, which enable us to achieve the production capacity more than 30,000 Sqm per month.

BESTONE HIGH TECH MATERIALS CO., LTD. (hereafter referred to as BESTONE) warrants to the original buyer that the Quartz Surfaces, which have been manufactured and fabricated by BESTONE, are free from Manufacturing Defects. Any claim of manufacturing defects shall be made either within 30 days after receiving the Quartz Slab/Surfaces or before installation at the site. If any manufacturing defect occurs, BESTONE will at its option, repair or replace the defected Quartz Surfaces. In case of replacement, the same quantity (number of slabs) will be supplied for free. BESTONE shall not cover the costs for transportation, fabrication, installation, or any other physical and/or moral damages.

1.Packing Details:

1.Quartz stone slabs packed in wooden frames suitable for ocean shipment.

2.Each slab is covered and protected by plastic film.

3.15pcs of 2cm slabs packed each bundle,and 7 bundles fit in a 20’GP container.

4.10pcs of 3cm slabs packed each bundle,and 7 bundles fit in a 20’GP container.

5.Unit weight of 2cm slab is 48kg/Square meter and 3cm slab is 72kg/Square meter.

2.Delivery

15-30 days from receipt of deposit.

Boasting a dedicated team of over 200 members devoting to R & D, production, marketing and after-sales service for the products and covering an area of 30,000 Sqm, at present BESTONE has Four sets of fully automatic production lines for slabs, which enable us to achieve the production capacity more than 30,000 Sqm per month.

1. Manufacturing quartz stone slab

2. Fabricate quartz counter top / vanity top / table top

3. Standard wood package or customized package

4. Customized Logo Printed / Sprayed / Labeled

5. OEM Color / Design

6. Stock slab retail

7. Prefabricated top retail

8. Other service related to the product or projects

9.Our trade manager is 24*7 online.Emails can be replied within 24 hours.

10.We offer 10 years warranty for commercial projects and 12 years warranty for

residential projects.

1.Where should the quartz stone be used?

Quartz stone must be used indoor such as kitchen worktops, bathroom and vanity tops

and floor tiles, where are not exposed to direct sunshine.

2.Why should we use quartz stone other than natural stone?

Compared with natural stone, quartz stone has higher density and hardness, less water

absorption, more durable and less maintenance, and better consistent color tone.

3.What sizes of quartz stone slabs are available from BESTONE?

BESTONE standard slab sizes are 126”*63” (3200*1600mm) and 118”*55” (3000*1400mm),and other customized sizes (2200~3200mm) *(1000~1600mm) are also available.

4.How does BESTONE pack the quartz stone slabs?

BESTONE packs the slabs with wooden crate made of 80*80mm solid wood, and surface of

slabs are protected by plastic film.

5.How does BESTONE ship the quartz stone slabs?

BESTONE ships the slabs in 20’ GP or OT container, 7 bundles fit a container in which 15

slabs of 2cm or 10 slabs of 3cm each bundle.

6.Is it possible to inspect the cargos in BESTONE factory before loading?

Yes, all customers are warmly welcome to inspect the cargos before loading.

7.Is it possible to do the OEM with BESTONE?

Yes, BESTONE provides the OEM service by printing customer’s Logo or company name.

Company Advantages

· Bestone custom stone solutions is fabricated utilizing the sophisticated production equipment and facilities.

· This product has passed related qualifications and international certifications.

· Bestone High Tech Materials Co., Ltd. offers reliable and high-quality services.

Company Features

· Bestone High Tech Materials Co., Ltd. is internationally competitive in the market of custom stone solutions.

· We have an excellent design team. The designers are experienced enough to timely understand the evolving needs of customers and the dynamic trends in the custom stone solutions market.

· Our company bears social responsibilities. With our environmental programs, measures are taken together with our customers to actively conserve resources and reduce carbon dioxide emissions in the long term.

Application of the Product

Our custom stone solutions is widely used in multiple industries and fields.

Bestone insists on providing customers with reasonable solutions according to their actual needs.